Oceans in Peril

Each year, tens of thousands of tons of crude oil are accidentally spilled into the world’s oceans due to pipeline ruptures, tanker accidents, offshore rig failures, or sabotage. These oil spills wreak havoc on marine ecosystems, endanger countless species, and destroy the livelihoods of coastal communities. While traditional cleanup methods like chemical dispersants, skimming, and burning have been used for decades, they are often slow, costly, and ecologically damaging.

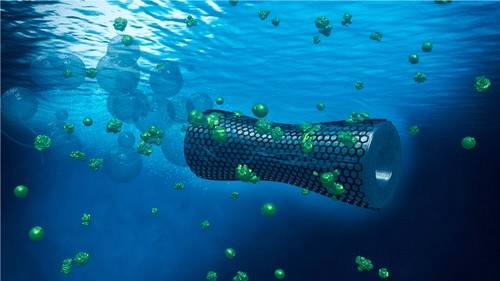

But in laboratories and pilot projects across the world, researchers are now turning to a cutting-edge technology with the potential to transform how we respond to oil disasters: magnetic nanomaterials.

The Science Behind the Solution

At the heart of this innovation are superparamagnetic iron oxide nanoparticles (SPIONs)—tiny particles less than 100 nanometers in diameter (about 1,000 times smaller than a human hair). When coated with hydrophobic (water-repellent) and oleophilic (oil-attracting) substances, these particles exhibit a remarkable ability to selectively bind with oil while ignoring water.

The magic happens when these coated nanomaterials are dispersed over an oil spill. The particles immediately bond with the oil, forming a magnetic-oil mixture. Using powerful external magnets—often mounted on drones or boats—cleanup crews can then extract the contaminated material quickly and efficiently.

Traditional Methods vs. Magnetic Nanotech

Let’s examine how magnetic nanomaterials compare with conventional oil spill response techniques:

| Method | Drawbacks | Magnetic Nanomaterials |

|---|---|---|

| Chemical dispersants | Toxic to marine life; persistent environmental residue | Non-toxic, eco-friendly |

| Skimming | Slow, limited by wave conditions and oil type | Fast, works even in rough water |

| Burning | Releases harmful gases; only partially effective | No harmful emissions; nearly total recovery |

| Manual recovery | Labor-intensive, time-consuming, and risky for workers | Remote-operated and safer |

Real-World Applications and Research

1. MIT’s Breakthrough Study

In 2012, a research team at the Massachusetts Institute of Technology (MIT) demonstrated a successful prototype using magnetically responsive ferrofluids. When exposed to an oil-contaminated water surface, these fluids rapidly absorbed the oil, which could then be pulled out using magnets. The process showed 99% efficiency in lab settings and was able to separate oil even when diluted to less than 1% concentration.

2. Indian Institute of Technology (IIT) Madras Innovation

In 2023, IIT Madras developed a reusable magnetic nanomaterial coated with silica and a special hydrophobic layer. This material proved effective not only in lab environments but also in simulated ocean conditions. Their model could recover more than 95% of spilled oil, and the nanomaterial could be reused up to 70 times without losing effectiveness—an important economic and environmental advantage.

3. Pilot Project in the Gulf of Mexico

In 2024, after a minor spill near the Louisiana coastline, the U.S. Environmental Protection Agency (EPA) partnered with a start-up called OceanMagTech to test a magnetic nanomaterial-based cleanup. The results were promising: over 90% of the surface oil was recovered within 6 hours, using only one-third the manpower typically required.

Why It Matters

✅ Fast and Efficient Oil Separation

Magnetic nanomaterials bind with oil in seconds and can be collected rapidly—even in turbulent waters—making them ideal for emergency situations.

♻️ Reusable with No Loss of Performance

Unlike traditional sponges or dispersants, many magnetic nanoparticles can be cleaned and reused dozens of times, making them more sustainable and cost-effective in the long term.

🌱 Eco-Friendly and Safe for Marine Habitats

These materials do not introduce harmful chemicals into the water and pose no threat to aquatic organisms, coral reefs, or birds. In fact, they can help reduce the secondary pollution associated with other response techniques.

🚨 Ideal for Rapid Emergency Response

Because magnetic cleanup kits can be compact and deployed quickly by air or sea, they offer a scalable solution for small or large spills—especially in hard-to-reach areas.

Challenges to Overcome

Despite their promise, magnetic nanomaterials aren’t a magic bullet just yet. Here are some of the key hurdles:

- Production Cost

Although prices have dropped significantly over the past decade, producing magnetic nanomaterials at scale is still more expensive than conventional dispersants. - Magnet Handling in the Field

Large-scale magnetic retrieval systems need to be robust, portable, and corrosion-resistant to function reliably in marine conditions. - Material Recovery and Recycling Logistics

After cleanup, the magnetically bonded oil needs to be separated from the nanoparticles. While this is possible through heating or solvent treatments, standardizing these processes for field operations is still in development. - Long-Term Environmental Testing

Even though nanomaterials are designed to be safe, their behavior over long periods in marine ecosystems is still being studied. Regulatory bodies are cautious and require extensive testing before approving widespread use.

The Future Outlook

The global oil spill management market is projected to reach $140 billion by 2030, and magnetic nanomaterials are poised to occupy a significant portion of this rapidly evolving landscape.

Startups and research labs around the world—from Sweden’s Chalmers University to Korea’s Yonsei University—are racing to optimize nanomaterial composition, reduce costs, and create mobile magnetic recovery units. Some designs even envision autonomous robotic drones carrying both nanomaterial sprayers and magnetized arms for remote or underwater cleanup.

Further innovations include biodegradable nanomaterials and AI-integrated sensors that detect oil concentrations in real time to optimize material deployment.

A Greener Way Forward

Oil spills have long been viewed as unavoidable disasters with no perfect solution. But magnetic nanotechnology challenges that narrative. By combining the power of materials science, environmental engineering, and nanotechnology, humanity now has a chance to respond to oil disasters without making the problem worse.

Imagine a future where every port, coastal region, and shipping lane is equipped with rapid-response drones, loaded with eco-safe nanomaterials and guided by real-time satellite data. Oil spills might still occur—but our response can be smarter, faster, and far less harmful.

Final Thoughts

Innovation doesn’t just mean faster phones or smarter cars—it also means safeguarding the environment with cutting-edge solutions. Magnetic nanomaterials represent one of the most promising frontiers in environmental protection technology. They don’t just clean up oil—they clean up the way we think about responsibility, sustainability, and science.

Stay curious. Stay inspired.

🌌 Follow Bobler News for more mind-expanding journeys through space, science, technology, and the wonders of innovation.

More Stories

IndiGo Plunges Into Crisis: Questions Over Airline Planning

Asia at Boiling Point: How Weather Is Rewriting the Region’s Future

Maithili Thakur: From Folk Singing Sensation to Rising Political Star